Streak Slit Camera Remote Device

The goal was to design a remotely operated vertical sliding mechanism for a streak slit camera, ensuring precise light alignment through a slit and compatibility with existing hardware.

My Role in the Project

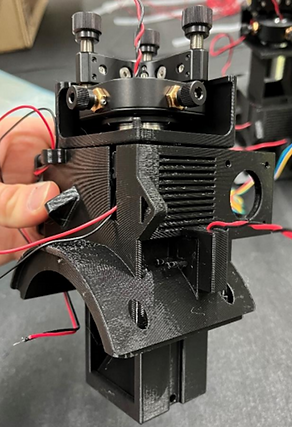

I designed the cable management and integration of the electro-mechanical system, developed the rack-and-pinion mechanism, and fine-tuned the assembly for precision. I also sourced components and managed prototyping and manufacturing.

Target Users and User Testing

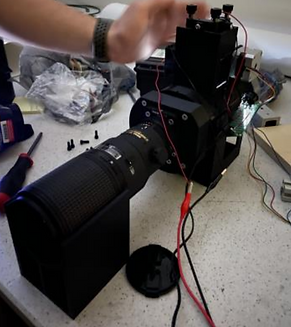

The target users are researchers and technicians in optical or scientific labs requiring precise, repeatable light alignment for streak slit cameras.

Initial tests showed poor sliding clearance in the rack-and-pinion system, resolved by iterating the fit. Light alignment issues were addressed by adding set screws, ensuring repeatability and precision.

Preliminary Work and Challenges

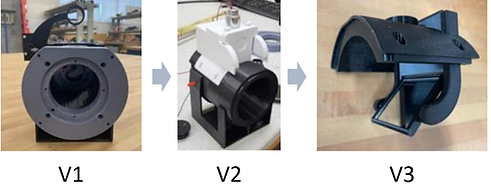

I researched rack-and-pinion systems and light alignment techniques, creating CAD models to simulate movement. Prototypes tested sliding clearance and alignment accuracy, with component sourcing prioritized for availability.

Challenges included achieving exact alignment, ensuring remote operability, 3D-printing over 50% of the parts, and sourcing easily replaceable components. The mechanism needed to fit existing hardware without requiring extensive modifications.

Final Product and Discussion

The final device is a remotely operated, precise vertical sliding mechanism with a rack-and-pinion system, integrated set screws for alignment, and compatibility with existing hardware using 3D-printed and off-the-shelf components.

This project enhanced my skills in electro-mechanical design and precision engineering. Solving alignment challenges through iterative prototyping underscored the importance of adaptability in meeting strict technical requirements.