BABATA

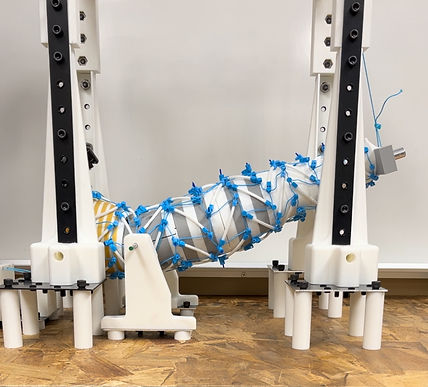

The BABATA apparatus was designed to test the bending and torsional stiffness of a human arm using a 3D-printed arm brace array, ensuring modularity, accurate arm representation, and biomechanical integrity.

My Role in the Project

I led the design and assembly, creating the modular structure and 3D-printed Multi-stiffness Expandable Tensegrity Structure (METS). I ensured biomechanical accuracy and conducted all the manufacturing and post-processing.

Target Users and User Testing

The target users are biomechanical researchers and students in labs studying arm stiffness and mobility, requiring a modular and accurate testing apparatus. Future users would be physical therapy patients or healthy people desiring an arm brace for specific workouts.

Early tests showed the METS array was too rigid, limiting arm movement. I adjusted the structure’s unit cell size and shape for better flexibility. Users also requested easier assembly, addressed by simplifying connection points.

Preliminary Work and Challenges

I researched human arm biomechanics and tensegrity structures, creating CAD models of the arm and METS. Prototypes tested the array’s stiffness, and assembly processes were refined for modularity and ease of use.

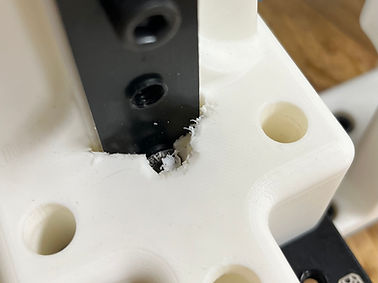

Challenges included replicating human arm dimensions, maintaining general biomechanical principles, and ensuring modularity for easy stiffness adjustment. The 3D-printed array needed to balance flexibility and strength.

Final Product and Discussion

The final BABATA apparatus is a modular, biomechanically accurate system with a 3D-printed METS array installed within it. It effectively tests arm stiffness and is easily reconfigured for various experiments.

This project deepened my understanding of biomechanics, modular design, and modeling for compatibility with off-the-shelf parts. The iterative refinement of the METS array highlighted the value of balancing material properties with functionality, resulting in a versatile research tool.

.jpg)